HDS-14LSX

SKU# 5175171

6,350-kg. Capacity / Alignment Lift / Extended / Includes Turnplates and Slip Plates

The legendary, 6,350-kg. capacity HDS-14LSX alignment lift pulls double duty as both car lift and alignment system. We’ve integrated industrial-strength slip plates and turn plates right into the runways to maximize convenience. The wheels respond to every adjustment with virtually no resistance.

Alignment Lift System Offers 6,350-kg. of Pure Lifting

BendPak's HDS-14LSX alignment lift is engineered to meet the strenuous demands of your toughest professional lifting jobs. Designed into the HDS-14LSX alignment lift is a long list of crucial features that improve safety, durability and productivity, ensuring your BendPak is the absolute best car lift you can buy.

This is the sturdy beast you want as the backbone of your shop, especially if you service large, low ground-clearance vehicles. Our alignment system features front turn plates and rear slip plates built right into the runways. The wheels always respond to your adjustments with no resistance or hassle. We call it “free-floating.” You’ll find it unbelievably easy.

Slip plates

Multi-caster slip plates in the back and turn plates in the front allow for extremely precise, free-floating alignment.

Turn plates

Dual, recessed turn plate pockets allow you to position the corrosion-resistant, galvanized turn plates in the location best suited for individual vehicle positioning. These turn plates provide more clearance for equipment installations.

Dual-hub cable sheaves

This BendPak alignment lift comes standard with robust 267 mm diameter cable sheaves within the runway and cross tubes and 57 mm diameter sheave axles that are equally durable. Both contribute to the longevity and low-maintenance cost of owning and operating your lift.

Heavy-duty aircraft cable

A 13 mm diameter 6 x 25 aircraft-quality stainless-steel lifting cable runs through each of the four columns. Designed for non-stop use and totally resistant to rubbing and other abrasions (e.g., weather, chemicals, hydraulic oil).

Adjustable height locking positions

Get your alignment lift to just the right height. No need to reach or bend for the turn plates, as every few inches, each post column features a lock position for your convenience.

Built-in lubrication

Grease fittings are included on every BendPak lift, so you can focus on the alignment of your wheels without worrying about the lubrication of your cable sheaves. BendPak makes it easy to keep an eye on your grease nipples, which only require periodic maintenance. Just peek inside the structure before, during or after using your alignment lift to see how the fittings are doing.

Flow restrictor

In the extremely unlikely event of a hose rupture, BendPak’s unique hydraulic flow divider provides a safe, even descent, thus keeping your alignment lift structure safe and ready to go after you address the situation. We highly doubt you will ever encounter this situation with your lift.

Spring-loaded safety locks

As the alignment lift rises to your preferred service level, springs engage the locks into place at each ladder position. The adjustable nature of the spring-loaded, multi-locking structure offers you the comfort of knowing that you’re safe to lift, even if there’s a slight slope in your garage.

Push-button pneumatic lock release

A simple push-button pneumatic lock release makes lowering operations simple and fast. Aircraft-quality stainless steel and aluminum pneumatic cylinders provide years of trouble-free service.

Secondary lock system

A slack-cable lock is your backup safety mechanism that’s ready at all times to shut off the alignment lift in the event of dangerous cable slack.

Integrated design

All cables, sheaves and airlines, as well as the single hydraulic cylinder, run internally through the lift structure. This optimizes aesthetics and safety in way that has come to define the BendPak brand.

Electric-hydraulic power system

No maintenance necessary! The electric-hydraulic power system features ergonomically located controls for easy operator access during repetitive daily use.

Longer approach ramps

Longer ramps make it easier to load low ground-clearance vehicles onto the car lift structure. Alignments on these vehicle types are no hassle, and of course, larger vehicles can glide on just as easily.

Flexible protective conduit

An extra-tough yet flexible conduit protects all airlines and hydraulic hoses from daily wear. Your alignment lift is safer and operations can be handled more confidently when you know your cables won’t deliver sudden, unfortunate electric shocks, ruptures or fluid leaks.

Rolling jacking beams

Optional rolling jacking beams make a great addition to increase service capacity. Bridge jacks raise the front or back of vehicles, so wheel and brake service can be performed without moving to a two-post lift or scissor lift. Use two jacks to raise the entire car. Telescoping arms and frame contact pads extend over runways and target the vehicle frame’s lifting points. Runways are fully adjustable for different tread widths. Three locking positions offer additional operator control.

Choose extended frames

The HDS14LSXE alignment lift is designed for extended-length vehicles, such as trucks and vans. The runways and overall length are extended by 762 mm. With runways now 5,817 mm in length, some very long vehicles can fit easily on the car lift. If your service bay demands these vehicle types, an extended length alignment lift is absolutely necessary to perform wheel alignments.

Features

- 6,350-kg lifting capacity

- CE Approved and Certified. Meets or exceeds the standards prescribed by European Standard EN 1493

- Two runway lengths to choose

- Heavy‐duty turn plates and integrated rear slip‐plates included

- Multi‐position turn plate pockets

- Automatic leveling system

- Multiple auto-leveling locking positions

- Runways include rail‐kit for optional accessories

- Electric / hydraulic power system

- Single hydraulic cylinder mounted underneath runway

- Fully enclosed lifting cables, safety locks, and sheaves

- Internal "Anti-Sway" slider blocks in each column

- Features oversize sheaves and heavy‐duty 13 mm aircraft cable

- Rugged 25 mm roller axles and oversize self‐lubricating cable sheaves

- Multi‐position safety locks in each column with push‐button safety release

- Runways adjust for different tread widths

- Optional 3,175-kg. capacity jacking beams available (Model RBJ7000)

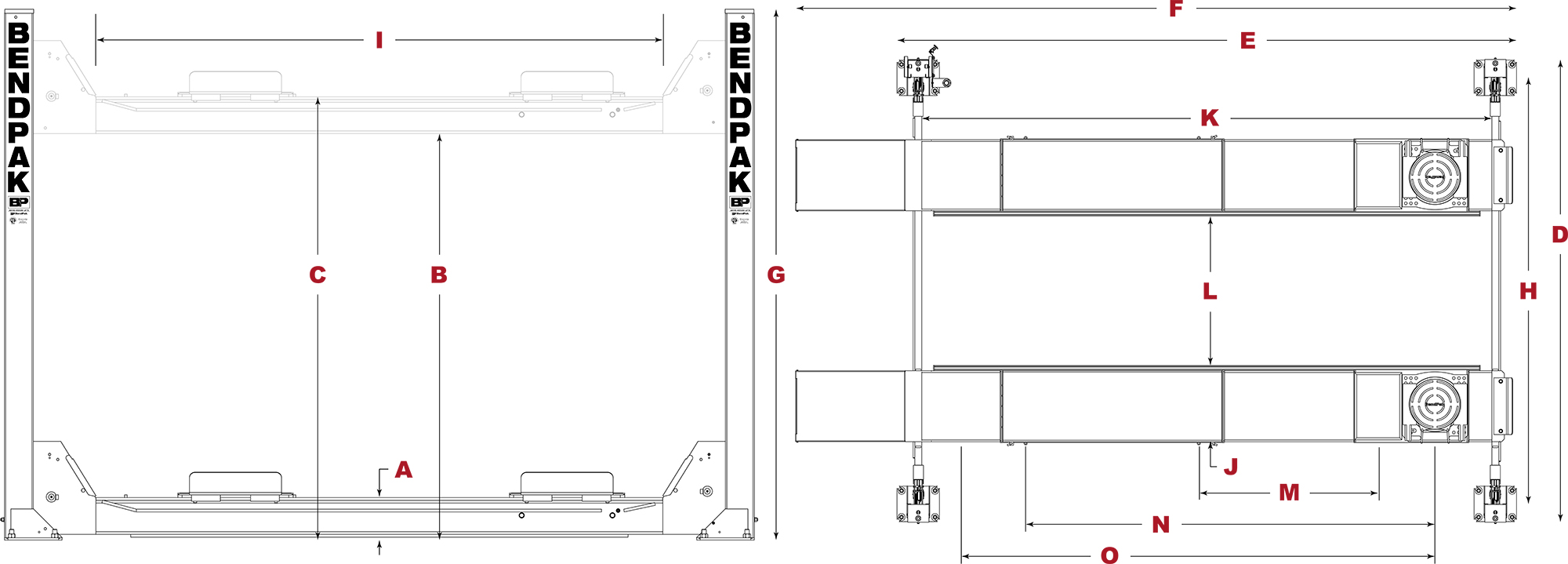

HDS-14LSX Specifications

Capacity

Rise

Outside Dimensions

Inside Dimensions

Runways

Alignment

Minimum Wheelbase

Locking

Power Unit

Shipping

Note: An air supply (minimum: 30 psi / 3 CFM) is required for the safety-lock mechanisms to disengage. It is solely the responsibility of the end-user to provide, install and maintain the air supply.

Note: Not all BendPak lift models meet the standards as prescribed by ANSI/ALI ALCTV-2017 or ANSI/UL 201. Consult www.autolift.org for a complete list or contact BendPak via contact@bendpak.com.

BendPak USA

BendPak USA BendPak UK

BendPak UK BendPak Australia

BendPak Australia BendPak South Africa

BendPak South Africa BendPak Canada

BendPak Canada BendPak Mexico

BendPak Mexico

Catalogs

Catalogs